-

Call Now ! +86 177 2978 0576

Call Now ! +86 177 2978 0576 -

Email Now sale@kfqizhongji.com

Email Now sale@kfqizhongji.com

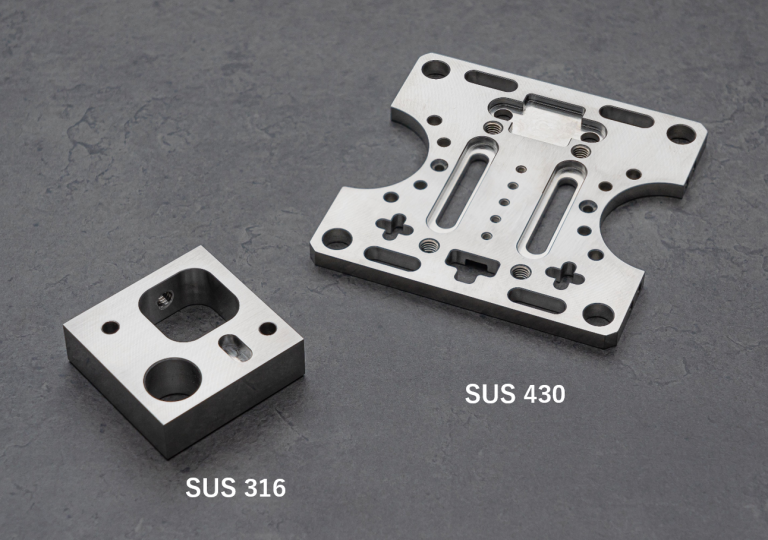

In the manufacturing industry, there are two types of parts - universal and interchangeable parts, which are produced in accordance with national or industry standards, and special parts that need to be designed specifically for certain products. These special parts are called non-standard parts. Non-standard parts are unique and cannot be substituted with any other parts due to their customized production process.

Features of Non Standard Parts

Givens provides unique vehicle parts that are precise, accurate, and fit for special components.

• Unique Non Standard Parts

Every non-standard component is tailored to fit the specific product design or production process. As a result, they are one-of-a-kind and do not have any alternatives. This implies that their quality and performance play a crucial role in determining the quality and performance of the entire product.

• High Precision

Non-standard parts are those that have to meet specific requirements, such as high-precision products or products used in special environments. As a result, they have very strict accuracy requirements, making it necessary to control every detail during the design and production process to ensure that the product requirements are met.

• High Cost

Customized parts cost more to produce due to their unique specifications, but are essential in some cases to meet specific product requirements.

• Longer Production Cycle

Customization of non-standard parts takes longer in the production cycle as they require specific modifications. To meet product requirements, various design and production stages are involved. This implies that planning and arrangement for customization of non-standard parts must be done in advance during the product design and production process.

Non-standard parts are crucial in the manufacturing industry, especially in high-precision products such as precision machine tools and measuring instruments. The quality and performance of non-standard parts have a direct impact on the overall quality and performance of the product.

Additionally, parts used in challenging environments like aerospace and petrochemical fields require high durability and reliability, as well as adaptability to the harsh working conditions. Therefore, many parts need to be customized, emphasizing the significant role of non-standard parts.

With over 10 years machining experience, KUNFENG Steel leverages state-of-the-art machinery and a highly skilled workforce to deliver precision parts machining services that surpass industry standards. By employing gantry CNC machine, such as turning, milling, boring, we keep manufacturing intricate parts with tight tolerances, enabling agricultural machining to operate flawlessly even under demanding conditions.