-

Call Now ! +86 177 2978 0576

Call Now ! +86 177 2978 0576 -

Email Now sale@kfqizhongji.com

Email Now sale@kfqizhongji.com

304 stainless steel, also known as 18/8 stainless steel, is an austenitic stainless steel. Its name comes from its chemical composition, which contains 18% chromium (Cr) and 8% nickel (Ni). These two elements give 304 stainless steel excellent corrosion resistance and toughness. In addition, 304 stainless steel also contains small amounts of carbon (C), silicon (Si), manganese (Mn), phosphorus (P), sulfur (S) and other elements to optimize its performance and processability.

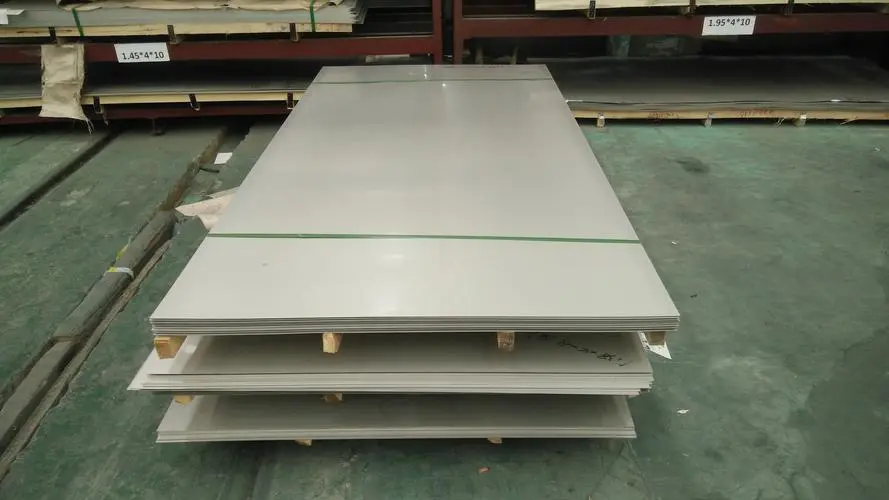

The production process of stainless steel plates mainly includes steps such as smelting, continuous casting, hot rolling, cold rolling, annealing and finishing. First, the required raw materials are mixed in a certain proportion and smelted at high temperature to form stainless steel molten steel. The molten steel is then cast into billets through a continuous casting machine. Next, the steel billet is hot rolled through a hot rolling mill to form a steel plate with a certain thickness and width. The hot-rolled steel plates are then cold-rolled to obtain higher dimensional accuracy and surface quality. Finally, annealing is used to eliminate the stress inside the steel plate and improve its corrosion resistance and toughness. The finishing stage includes cutting, grinding, packaging and other steps to meet the needs of different customers.

Advantages of 304 stainless steel plate

● It has good corrosion resistance and can resist the erosion of most acid and alkali solutions, so it is widely used in chemical industry, food, medical and other fields.

● It has high toughness and ductility and is easy to be processed into various shapes and sizes to meet various application needs.

● The surface is smooth and beautiful, has good decorative effect, and is suitable for various high-end occasions.

● It is non-toxic and harmless, meets environmental protection and health standards, and is widely used in food, medical equipment and other fields.

Scenes to be used

● With its beautiful appearance and excellent corrosion resistance, it is widely used in the field of building decoration, such as curtain walls, doors, windows, stair handrails, etc.

● It is widely used in the chemical industry, such as storage tanks, reactors, pipelines, etc. Because of its strong corrosion resistance, it can withstand the erosion of various chemical substances.

● It complies with food safety standards and is widely used in the manufacture of food processing equipment, tableware, kitchenware and other products.

● It is non-toxic and harmless and has good biocompatibility, so it is widely used in the field of medical devices, such as surgical instruments, dental equipment, infusion stands, etc.

● It is widely used in automobiles, ships, electric power, environmental protection and other fields, and is favored by users for its excellent performance and wide range of applications.