-

Call Now ! +86 177 2978 0576

Call Now ! +86 177 2978 0576 -

Email Now sale@kfqizhongji.com

Email Now sale@kfqizhongji.com

CNC machining service is the most cost-effective methods for on-demand metal parts. Lots of factors are determining the machining price.This article will give useful tips on how to reduce the cost to suite your budget.

What Determine CNC Machining Price?

1. Material

Metals and plastic is the most common machining materials. As a subtractive process, it tends to use more material than what will be on the final product. The type of metal being machined can have a significant impact on the price. Some metals are more expensive than others, and may require specialized tools and techniques to work with, which can increase the cost.

For example, machining titanium is generally more expensive than machining aluminum due to its higher density and hardness. What’s more, aluminum 6061 is the most common CNC machining metals, due to its blend of economical price and good machinability.

2. Machining

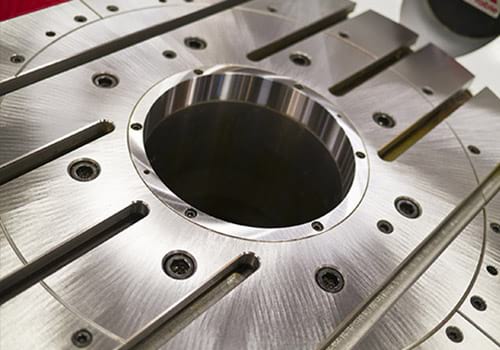

Machining technique can also affect the price. The two main types of machines used in CNC machining are mainly 3-axis machines and multi-axis machines. You can get 3-axis machining service and 5-axis machining-service with Chinese companies like KUNFENG, which offer a cheaper and precise metal machining.

CNC machining, for example, is generally more expensive than manual machining due to the cost of the equipment and programming required. However, CNC machining can offer greater precision and efficiency, leading to higher-quality parts.

KUNFENG Steel is a CNC manufacturing and metal machining company, including CNC machining services, CNC milling services, CNC turning services, laser cutting services and metal cutting and welding services.

3. Labor Cost

Large amount of automation involved in the CNC machining process leads a lot of staff costs.

Highly skilled machinist, the complexity of the part and the required level of precision increase the time and effort to machine the part, and then leading to a higher labor cost.

From programming to set up and post-processing, CNC machining process requires a lot efforts and labor costs. For example, CAD design and assembly manual labor cost.

Other factors that can affect the price of metal machining include the quantity of parts being machined, the required tolerances, the desired surface finish, and the lead time required to complete the machining process.

Based on the specific needs, these factors should be focused when selecting a machining service provider to ensure that they receive high-quality parts at a fair price.