-

Call Now ! +86 13390692151

Call Now ! +86 13390692151 -

Email Now sale@kfqizhongji.com

Email Now sale@kfqizhongji.com

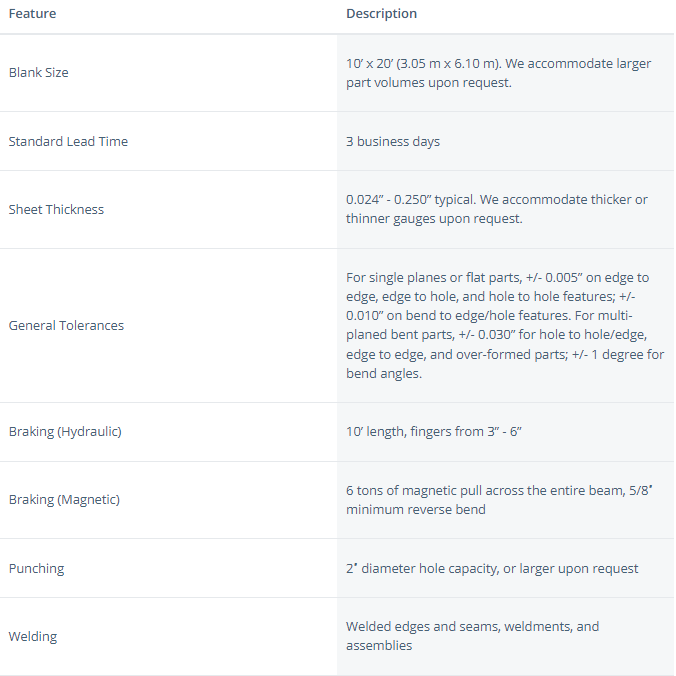

KUNFENG provide metal cutting and bending services for the fabrication of sheet metal parts. The automated cutting processes guarantee high precision and quality of ready parts. All parts can be subject to post-processing upon your request: coatings, heat-treatment and others. Common sheet meta

KUNFENG provide metal cutting and bending services for the fabrication of sheet metal parts. The automated cutting processes guarantee high precision and quality of ready parts. All parts can be subject to post-processing upon your request: coatings, heat-treatment and others.

Common sheet metal fabrication processes include waterjet cutting, plasma cutting, laser cutting, EDM, and bending, stamping and punching.

KUNFENG provide metal cutting and bending services for the fabrication of sheet metal parts. The automated cutting processes guarantee high precision and quality of ready parts. All parts can be subject to post-processing upon your request: coatings, heat-treatment and others.

Common sheet metal fabrication processes include waterjet cutting, plasma cutting, laser cutting, EDM, and bending, stamping and punching.

KUNFENG sheet metal forming services provide a fast and cost-effective solution for any parts that need to be made from 3D CAD files or engineering drawings. KUNFENG offers a range of sheet metal materials, including aluminum, copper, steel, and stainless steel. With a network of domestic and overseas fabricators, KUNFENG can supply any quantity of parts from low-volume, high-mix prototypes to high-volume production runs.

KUNFENG sheet metal forming services provide a fast and cost-effective solution for any parts that need to be made from 3D CAD files or engineering drawings. KUNFENG offers a range of sheet metal materials, including aluminum, copper, steel, and stainless steel. With a network of domestic and overseas fabricators, KUNFENG can supply any quantity of parts from low-volume, high-mix prototypes to high-volume production runs.